Article Key Points:

1. New Research at SLAC National Accelerator Lab at Stanford, where Gold Gets Stronger when subjected to laser pulses.

2. Lasers are the “bullets in space”

3. Having gold-plated armor means space stations, satellites, and spacecraft will need gold housing or cladding to endure all space voyages.

4. This Breakthrough is the Biggest and Bullish Gold Story since Space Exploration Started. (If you can think of a more significant Gold story than the one you are about to read, please write it up and send it everywhere you can.)

5. Preliminary Gold Demand Math Modeling starts at 22.4 Million ounces of Gold.

6. If the SLAC labs are accurate in their science, this will be the most significant industrial use of Gold ever recorded.

6. Video feature at the end of this article

Department of Energy’s SLAC National Accelerator Laboratory: Gold when zapped with high-energy laser pulses gets stronger

Gold Gets TOUGHER When Zapped by Lasers (SLAC Experiment) New Data shows 5 Kilograms of Gold per Satellite. In Space stations from 30 to 50 Kilograms of Gold.

New research, conducted at the Department of Energy’s SLAC National Accelerator Laboratory, illuminates the strange behavior of gold when zapped with high-energy laser pulses.

When certain materials, such as silicon, are subjected to intense laser excitation, they quickly fall apart. But gold does the opposite: it gets tougher and more resilient. This is because the way the gold atoms vibrate together – their phonon behavior – changes.

"Our findings challenge previous understandings by showing that, under certain conditions, metals like gold can become stronger rather than melting when subjected to intense laser pulses,” said Adrien Descamps, a researcher at Queen's University Belfast who led the research while he was a graduate student at Stanford and SLAC. “This contrasts with semiconductors, which become unstable and melt."

source - https://www.nanowerk.com/nanotechnology-news3/newsid=64670.php

Source - https://www.valencesurfacetech.com/the-news/gold-plating-in-satellites/

When you hear Gold advocates state things like "Gold has intrinsic value,"…well, it's an understatement. Gold has characteristics no other metal has

Gold is the most malleable and ductile metal; a single gram can be beaten into a sheet of one square meter or an ounce into 300 square feet.

Gold leaf can be beaten thin enough to become translucent.

The transmitted light appears greenish blue because gold strongly reflects yellow and red. Gold readily forms alloys with many other metals. These alloys can be produced to increase the hardness or to create exotic colors.

Native gold usually contains eight to ten percent silver, but often much more — alloys with a silver content over 20% are called electrum. As the amount of silver increases, the color becomes whiter, and the specific gravity decreases.

-

In industrial settings, one ounce of gold stretches into 5 miles of gold wire.

-

In the past and still used architecturally, 1 ounce of gold is pounded into "gold foil" covering the entire area of a pickleball court (around 300 sq feet)

-

Now, based on research from SLAC, we are learning that gold gets stronger when attacked by lasers.

-

This research by Stanford is a game-changer for aerospace and military.

-

And you can bet Militaries throughout the World (based on this new research) will be gobbling up as much gold as they can

-

So are the Central Banks around the Globe

-

So should you!

Gold is a great conductor of heat and electricity and is unaffected by air and most reagents.

Heat, moisture, oxygen, and most corrosive agents have a minimal chemical effect on gold, making it well-suited for use in coins and jewelry, gold-plating instruments, gold-plating satellites, gold-plating spacecraft, and use in space stations.

Gold Plating Uses in Aerospace & Satellites

Gold is a versatile and durable metal that finds extensive industrial applications in various fields, including aerospace and satellites. One of the primary uses of gold in aerospace is gold plating, which involves applying a thin layer of gold to metal or plastic surfaces. This process improves the appearance of the material and provides corrosion and wear resistance. Gold plating is commonly used in electrical components like wire, circuits, and connectors due to its excellent electrical conductivity. Additionally, gold has high corrosion resistance, making it ideal for moisture-rich environments in aerospace. It is also non-magnetic, allowing its use in components that require a non-magnetic environment.

New Research at Stanford SLAC Department of Energy Lab proves Gold gets stronger when attacked by lasers.

-

Gold is extensively used in aerospace and satellite applications.

-

Gold provides corrosion and wear resistance, improving the lifespan of components.

-

Gold plating enhances electrical conductivity and is ideal for moisture-rich environments and severe weather (harsh conditions like outer space)

-

Gold plating offers non-magnetic properties, making it suitable for specific components.

-

Gold plating is a versatile finish that can withstand extreme conditions in aerospace.

Benefits of Gold Plating in Aerospace and Satellites

Gold plating offers several advantages in aerospace applications. Firstly, it provides superior electrical conductivity compared to other metals, ensuring efficient performance of electrical components in satellites. Gold plating acts as a protective barrier, shielding underlying metals from oxidation and corrosion, thereby increasing their lifespan. It also offers excellent wear resistance, safeguarding components from the rigors of space travel.

Additionally, gold plating produces a highly reflective surface, reducing the absorption of solar radiation by satellites and helping to regulate temperature. Moreover, gold plating provides insulation, reducing electrical interference and enhancing communication capabilities. Overall, gold plating is a highly durable finish that can withstand extreme temperatures and harsh environmental conditions, making it an ideal choice for aerospace applications.

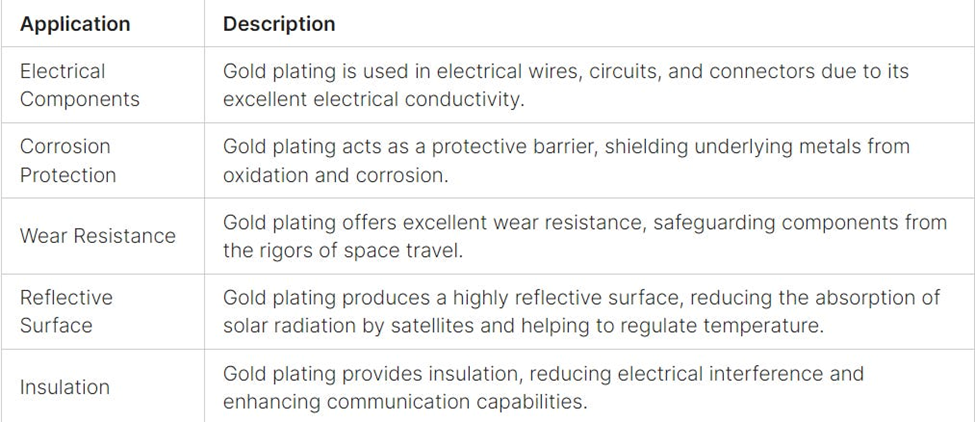

Below is a table showcasing the applications of gold plating in the aerospace industry:

Application Description Electrical Components Gold plating is used in electrical wires, circuits, and connectors due to its excellent electrical conductivity. Corrosion Protection Gold plating acts as a protective barrier, shielding underlying metals from oxidation and corrosion. Wear Resistance Gold plating offers excellent wear resistance, safeguarding components from the rigors of space travel. Reflective Surface Gold plating produces a highly reflective surface, reducing the absorption of solar radiation by satellites and helping to regulate temperature. Insulation Gold plating provides insulation, reducing electrical interference and enhancing communication capabilities.

In this section, we have highlighted the benefits of gold plating in aerospace and satellites. From superior electrical conductivity to corrosion protection and wear resistance, gold plating offers a range of advantages. It also creates a reflective surface, provides insulation, and can withstand extreme temperatures and harsh environmental conditions. These qualities make gold plating an indispensable choice for aerospace applications.

The Role Gold Plating in Satellites

Gold plating plays a crucial role in satellite technology. The process involves the application of a thin layer of gold to satellite surfaces. This gold plating serves as a protective barrier against damaging radiation, high temperatures, and other environmental factors. It acts as insulation, reducing electrical interference within satellites and ensuring optimal performance.

The usage of gold plating in satellites is cost-effective due to gold's durability and resistance to extreme conditions. The amount of gold used in satellites varies depending on the type and purpose of the satellite. Small CubeSats may use as little as 0.1g of gold, while larger satellites can utilize up to 5kg of gold.

Source - https://www.valencesurfacetech.com/the-news/gold-plating-in-satellites/

The type of gold plating used, such as electroplated gold or thick-film gold plating, also determines the amount of gold required.

Gold plating in satellites provides enhanced protection, insulation, and electrical performance, making it an indispensable element in satellite technology.

We’ve released 50 more sources and doubling down on Gold Demand Claim.

The 22.4 Million ounces of Gold listed above is just using some preliminary math modeling. The number is most likely double that amount. Why is that?

1. The table only included China, Russia, India, SpaceX, Blue Origin, NASA, and the US Military and did not include the other aerospace companies like Lockheed Martin, Boeing, Raytheon, or General Dynamics nor list countries like Australia, France, Germany, UK, Japan, South Korea and Israel

2. Also, this research is only two weeks old. Now that the whole world knows that Gold gets stronger under laser pulses and that lasers are the bullets of space, would you want to invest 100 Million dollars to Billions in Space Craft (satellites, space vehicles, space stations, rockets, space shuttles) but then say, Nah, I will pass on an extra $200,000 worth of Gold that is scientifically proven to provide as a protective shield for my investment. Jon Little states, "It would be like a Roman warrior saying, Today I shall fight without my bronze helmet and bronze shield; yeah, that's the smartest battle plan."

For more articles by Jon Forrest Little click here